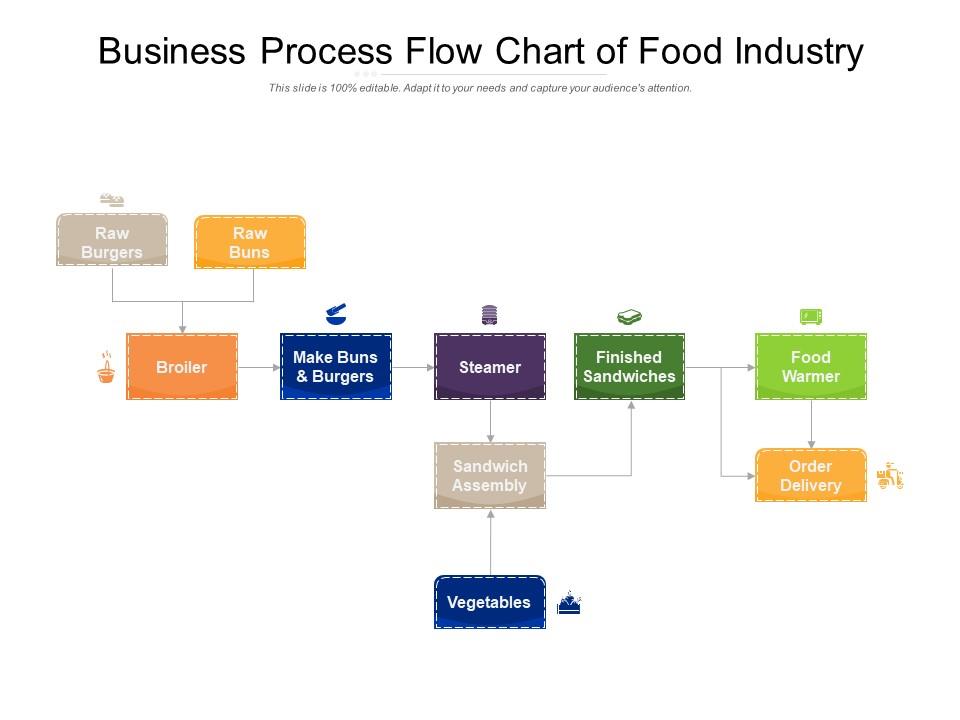

In contemporary business environments, precision and clarity are paramount, especially when depicting intricate operational processes. A well-designed food production flow chart template serves as an indispensable tool for organizations seeking to visualize, analyze, and optimize their manufacturing workflows. This foundational document provides a standardized, graphical representation of every step involved in transforming raw ingredients into finished food products, from sourcing and processing to packaging and distribution. Its utility extends across various departments, offering a coherent view that transcends linguistic and technical barriers, thereby fostering unified understanding and improved operational efficiency.

The strategic application of such a template is crucial for stakeholders across the supply chain, including production managers, quality assurance teams, logistics coordinators, and regulatory compliance officers. By providing a clear, sequential breakdown of activities, this structured form enables rapid identification of bottlenecks, redundancies, and potential areas for innovation or risk mitigation. It simplifies complex information, making it accessible and actionable for both technical personnel and executive leadership, ultimately supporting data-driven decision-making and continuous process improvement initiatives.

The Importance of Visual Organization and Professional Data Presentation

The human brain processes visual information significantly faster than textual data, making visual organization an essential component of effective business communication. Professional data presentation, particularly through tools like a well-structured flow chart, minimizes cognitive load and enhances comprehension. When complex processes, such as those in food production, are distilled into a clear visual narrative, it allows for immediate grasp of sequential steps, interdependencies, and potential deviations.

Data visualization is not merely about aesthetics; it is a critical strategic imperative that transforms raw data into actionable insights. A meticulously designed chart provides an intuitive interface for understanding operational dynamics, highlighting performance metrics, and facilitating the identification of critical control points. This professional approach to data presentation ensures that all relevant parties share a common understanding of the process, reducing misinterpretations and accelerating collaborative problem-solving. Effective chart design, encompassing elements like consistent symbolism and logical flow, is fundamental to conveying information accurately and efficiently, thereby bolstering an organization’s analytical capabilities.

Key Benefits of Structured Templates and Visuals

Utilizing structured templates and visual aids offers a multitude of advantages that directly impact operational efficiency and strategic planning. A primary benefit is the establishment of consistency in documentation across an organization. When every process is mapped using a uniform layout and standardized symbols, it eradicates ambiguity and ensures that all personnel interpret information identically, regardless of their specific role or department. This standardization is vital for maintaining high levels of quality control and operational fidelity in complex production environments.

Furthermore, these templates significantly enhance efficiency by streamlining the creation and updating of process documentation. Instead of designing a visual from scratch each time, users can leverage a pre-formatted structure, saving considerable time and resources. This efficiency extends to training new employees, who can quickly familiarize themselves with established workflows by reviewing clear, consistent diagrams. The structured nature of a food production flow chart template inherently minimizes errors by guiding users through a logical sequence, ensuring that no critical steps are overlooked during process mapping or analysis. Such precision is paramount in sectors where product quality and safety are non-negotiable, offering a robust framework for continuous improvement and compliance.

Adaptability Across Various Applications

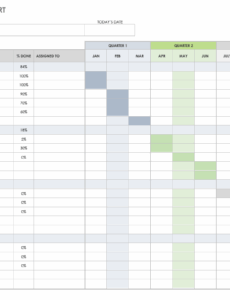

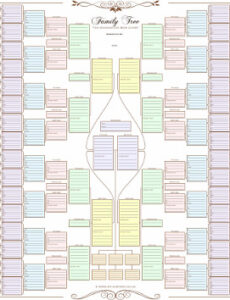

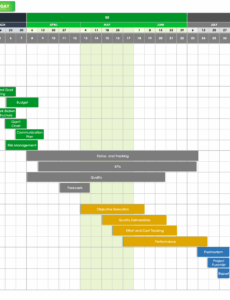

The fundamental principles embedded within this type of template extend far beyond its primary focus on food production, demonstrating remarkable adaptability across diverse professional and academic applications. Its core structure for sequencing tasks and illustrating relationships can be universally applied to various analytical and reporting needs. For instance, in business reports, it can effectively delineate strategic implementation plans, customer journey maps, or project management timelines, offering stakeholders a clear, stage-by-stage overview of complex initiatives.

Academically, students and researchers can adapt the underlying concept of a flow chart to illustrate experimental procedures, research methodologies, or the conceptual frameworks of theoretical models. For performance tracking, a modified version might serve as a visual performance dashboard, mapping key performance indicators (KPIs) against their contributing processes to identify areas for operational enhancement or celebrate successes. Similarly, in financial analysis, it could illustrate cash flow cycles, investment decision processes, or even the logical steps involved in risk assessment, providing a structured, visual aid that enhances comprehension and facilitates detailed review. The versatility of such a diagram lies in its capacity to break down any complex system into manageable, sequential components, thereby making it an invaluable tool for clarity and strategic insight across numerous disciplines.

Effective Scenarios for Utilizing a Food Production Flow Chart Template

A well-constructed food production flow chart template proves invaluable in a variety of specific operational and strategic contexts. Its structured format provides clarity and ensures thoroughness where precise process mapping is critical. The following scenarios represent key instances where employing this type of visual is most effective:

- New Product Development: Mapping the entire lifecycle of a new food product, from initial concept and ingredient sourcing to processing, quality control, packaging, and market release. This ensures all stages are considered and potential bottlenecks identified early.

- Quality Assurance and Control: Detailing the specific quality checkpoints and control measures at each stage of production. This helps in pinpointing where critical control points (CCPs) are implemented and how deviations are handled, crucial for HACCP plan development.

- Operational Optimization and Efficiency Studies: Analyzing existing production lines to identify redundant steps, areas of inefficiency, or opportunities for automation. The visual allows for rapid identification of improvement areas and process streamlining.

- Regulatory Compliance Documentation: Providing clear, auditable documentation for regulatory bodies, illustrating adherence to food safety standards, labeling requirements, and traceability protocols. This ensures that all necessary steps for compliance are visibly accounted for.

- Staff Training and Onboarding: Serving as a comprehensive training aid for new employees, enabling them to quickly understand complex production processes and their role within the overall workflow. Visual learning significantly accelerates comprehension.

- Troubleshooting and Root Cause Analysis: When a production issue arises, the chart provides a clear reference point to systematically trace back through the process, identifying the exact stage where the problem originated. This facilitates effective problem resolution and preventative measures.

- Supplier and Ingredient Management: Illustrating the flow of raw materials from various suppliers through different stages of processing, ensuring proper segregation, storage, and usage tracking. This is vital for managing supply chain integrity.

- Waste Reduction Initiatives: Pinpointing stages where waste generation is highest or where ingredients are underutilized, enabling targeted interventions to improve resource efficiency and reduce environmental impact.

These applications demonstrate how the template functions not just as a static document but as a dynamic tool for operational management, strategic planning, and continuous improvement within the food production sector.

Design, Formatting, and Usability Best Practices

Maximizing the utility of any visual documentation hinges on adhering to robust design and formatting principles, alongside a strong focus on usability. When creating or adapting a diagram, prioritize clarity and readability above all else. Use a consistent set of symbols for different process steps, decisions, and data inputs; industry-standard symbols often enhance universal comprehension. Employ clear, concise labels for each step, avoiding jargon where possible or providing immediate definitions when necessary. The flow of information should be logical and intuitive, typically moving from left to right or top to bottom, minimizing crisscrossing lines that can confuse the viewer.

Regarding formatting, maintain a uniform aesthetic across all pages or sections of the document. Utilize a clean, professional font that is easily legible in both print and digital versions. Strategic use of color can differentiate process stages or highlight critical elements, but overuse should be avoided to prevent visual clutter. For digital versions, ensure the diagram is responsive and scalable, allowing users to zoom in without loss of resolution. Hyperlinks can be embedded to connect specific steps to external documents, such as standard operating procedures or relevant data tracking spreadsheets, enhancing the depth of information available. When preparing for print, ensure adequate margins, and consider breaking extremely large diagrams into logical, interconnected subsections to maintain readability on standard paper sizes. The goal is to create a visual tool that is not only informative but also a pleasure to interact with, whether on screen or in hand.

The development and consistent application of a well-structured visual document like this ultimately elevate an organization’s capacity for effective communication and operational excellence. It transcends the basic function of merely documenting processes, evolving into a dynamic analytical instrument that underpins strategic decision-making and continuous improvement. By standardizing the visualization of complex workflows, it ensures that every stakeholder, from the production floor to the executive boardroom, operates from a shared, unambiguous understanding of operational realities and objectives.

This comprehensive approach to visual documentation represents a significant investment in clarity, efficiency, and error reduction. The data file becomes an invaluable asset for identifying opportunities for optimization, streamlining training protocols, and ensuring rigorous compliance with industry standards. Its enduring value lies in its ability to transform abstract processes into tangible, actionable insights, providing a reliable framework for progress in a demanding and ever-evolving industry.